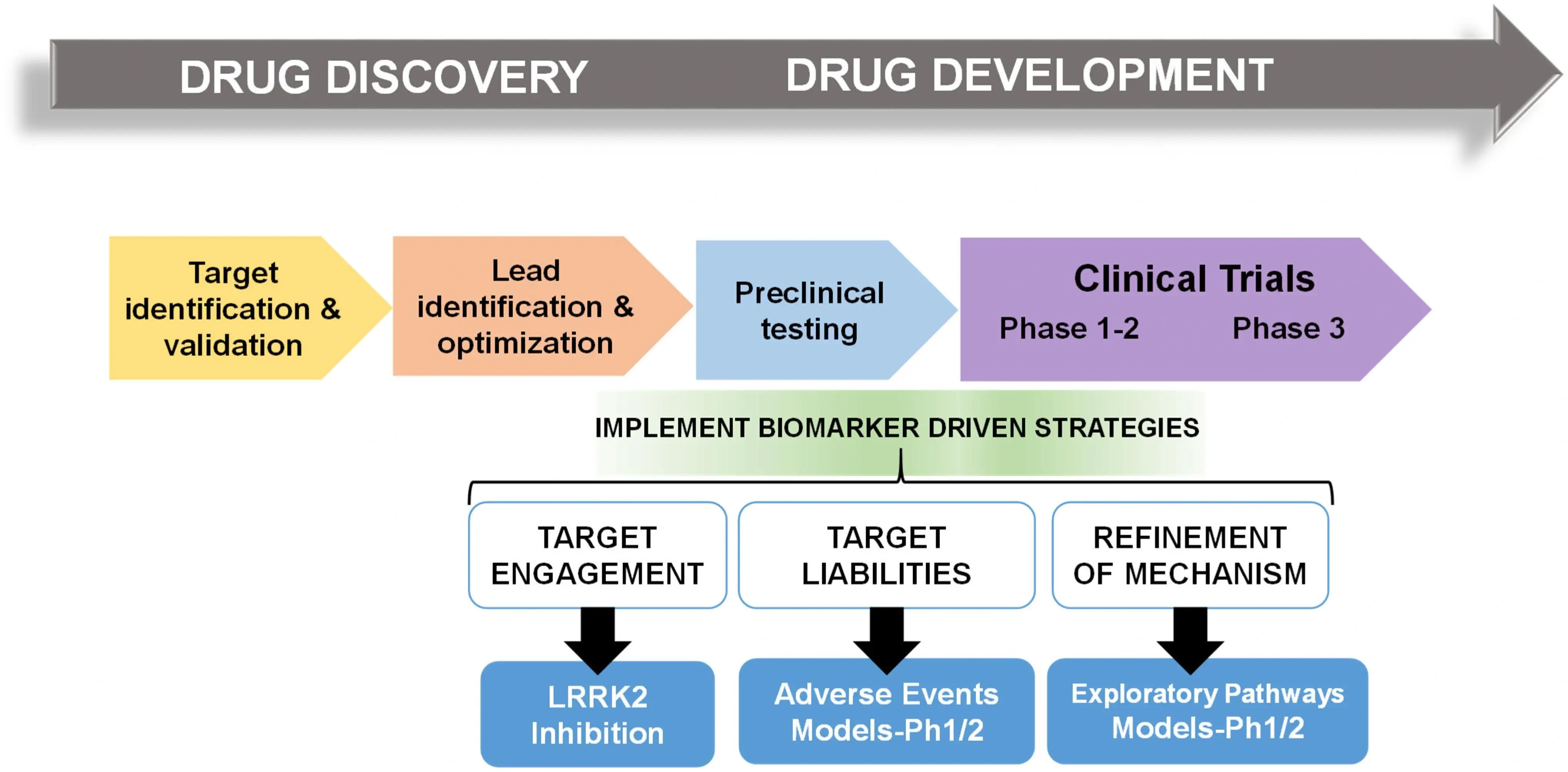

Compliance

Traceability is integral to regulatory compliance, audit preparation, and product recalls.

Documentation

DocSheets facilitates detailed documentation of product requirements to ensure comprehensive development.

Lifecycle Support

Traceability supports the entire product lifecycle, enabling developers to track and link requirements from inception to post-market maintenance.

Centralization

DocSheets provides a centralized location for joint viewing and updating of product requirements, resulting in a more harmonious collaborative environment.

Efficient Implementation

Efficient implementation of DocSheets reduces lead time through better alignment and proactive vetting and interpretation of requirements by all stakeholders.

Streamlined Development

Streamlined development is enhanced when everyone is working in sync to achieve company goals.

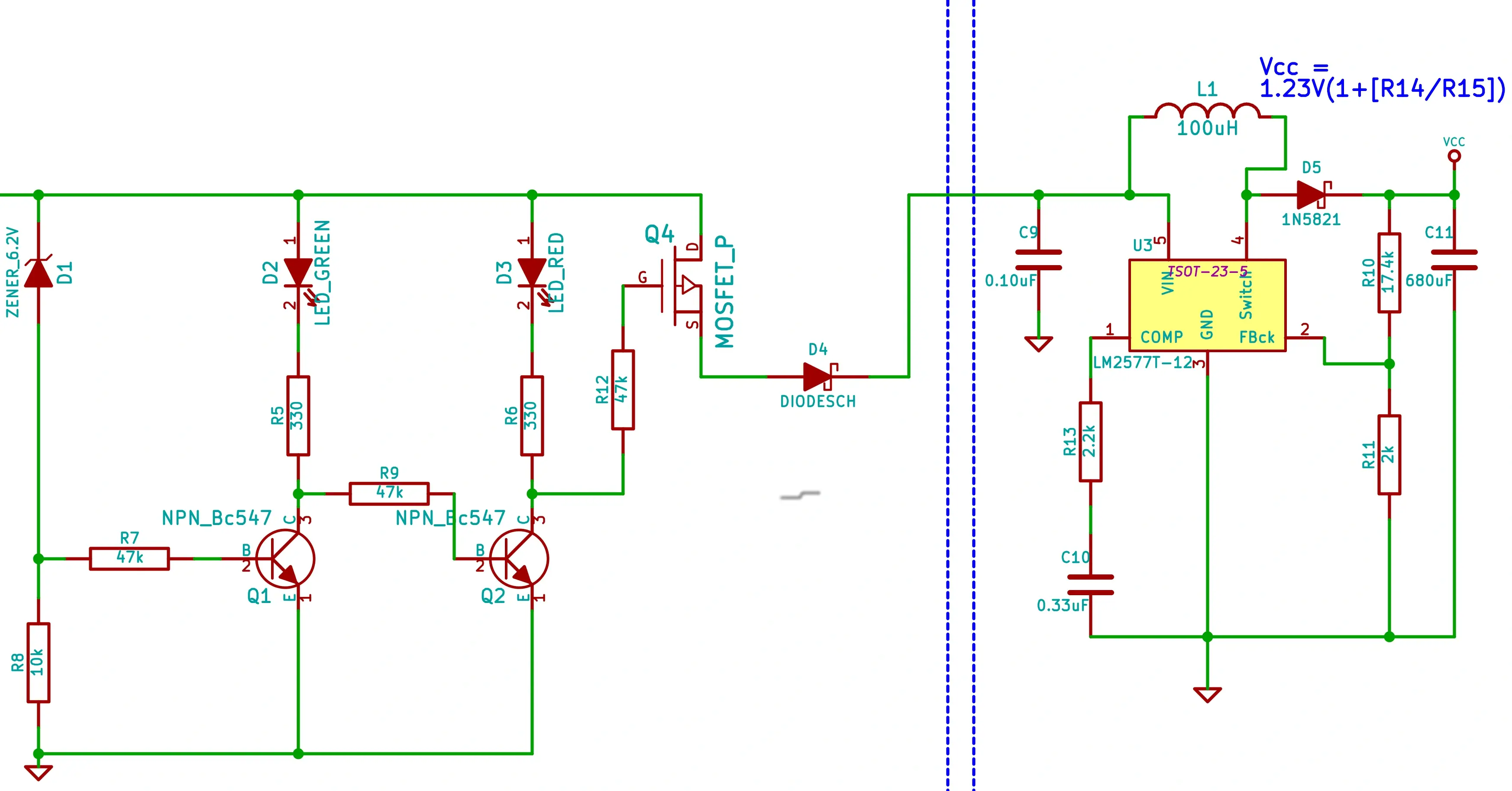

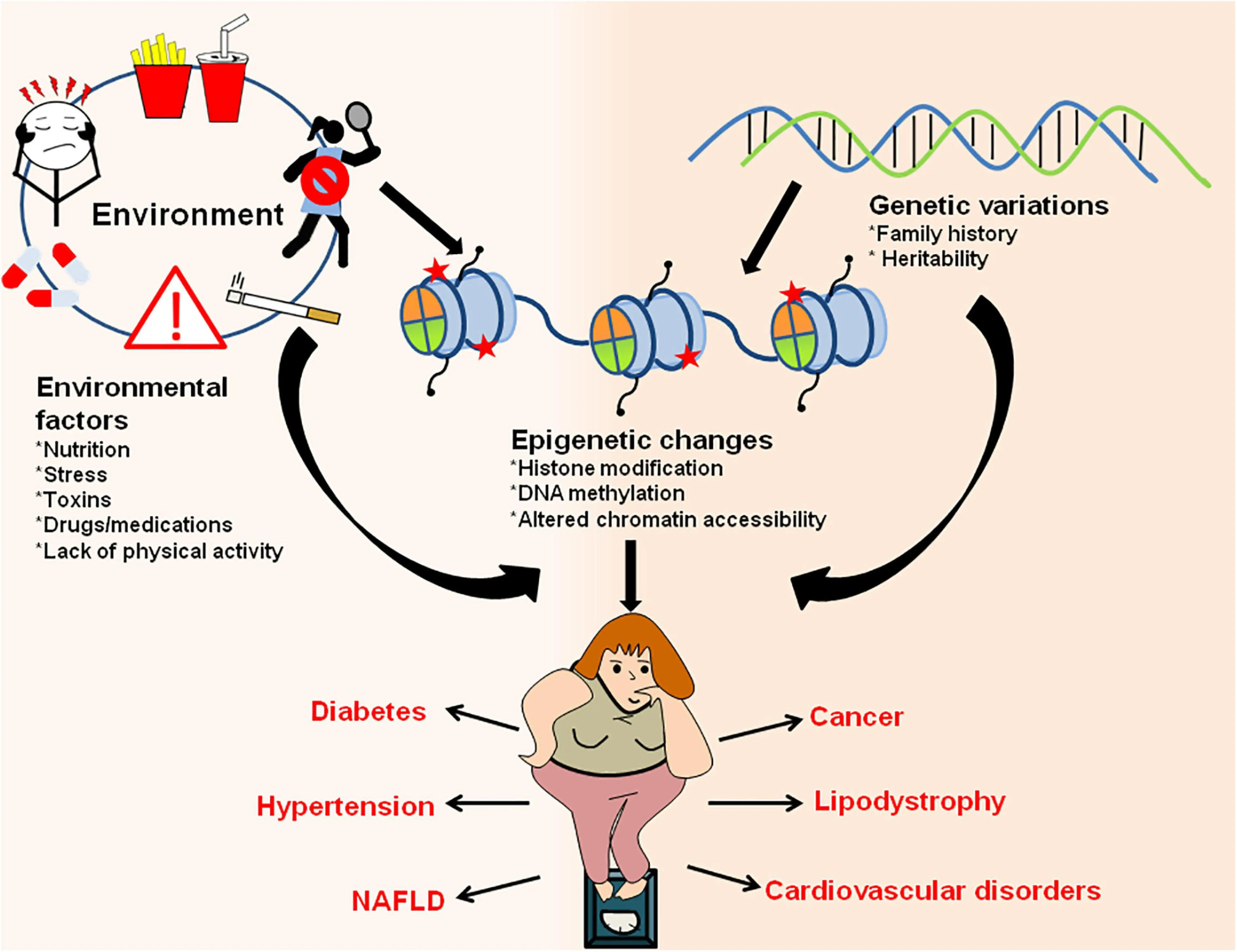

Identification

DocSheets encourages early identification of hazards and risks specific to the product development process.

Risk Analysis

The software supports risk analysis throughout the entire lifecycle of the product.

Risk Management

Risk management procedures are centralized to ensure all parties are accurately informed of all assessed risks.

Documentation

All documentation can be managed and kept up-to-date through DocSheets Software.

Maintaining Records

DocSheets maintains records of all changes in a complete audit trail to ensure proper monitoring of development activities.

Built-In Change Management

The tool provides a built-in change management process to keep all stakeholders informed throughout the development process.

Version History

Track and store all document versions in one centralized location.

Rollback Capability

Ability to roll back to a previous document version if required.

Access Control

Implement access controls to guarantee exclusive access to the current version.

Automation

DocSheets Software incorporates automated workflows to aid developers, such as requirements verification, traceability reporting, and change management.

Time & Cost Savings

The result of streamlining the process is a decrease in lead time and development costs.

Improved Data Management

Automating the product lifecycle also increases data accuracy to ensure decision-makers are using relevant information.

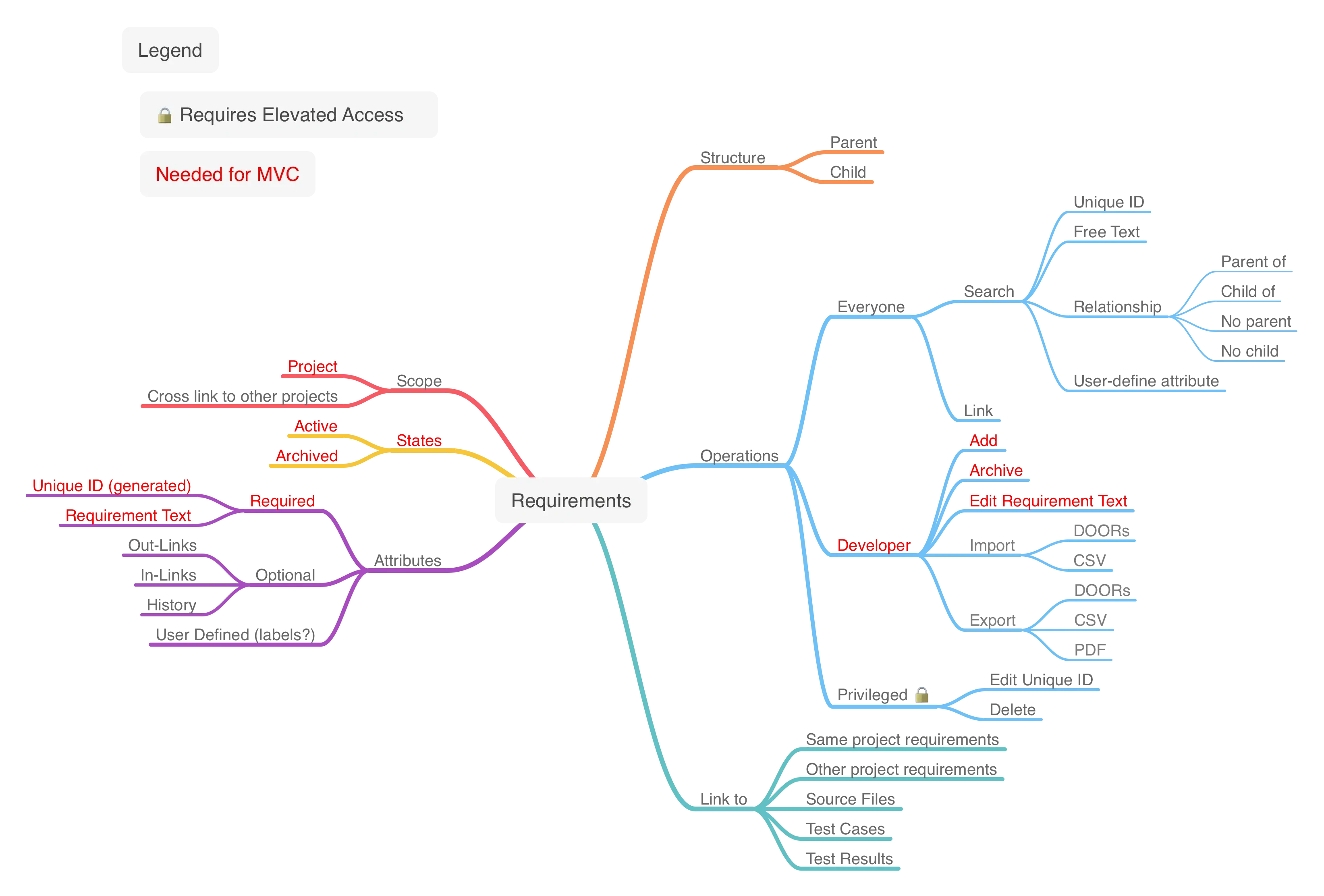

Testing

The software provides testing capabilities for products to ensure compliance, safety, and effectiveness.

Validation

DocSheets leverages established protocols and customizable workflows for product validation, ensuring all requirements are met and verified.

Compliance

DocSheets Software enables validated and updated production procedures, ensuring compliance, quality, and safety while adhering to regulations.